33KV Power Cables to BS 7835 NR/PS/ELP/00008

Application

The cables are used to distribute three phase a.c. electrical power supplies at nominal system voltages of 33KV to traction substations on D.C. electrified lines.

Standard

- NR/PS/ELP/00008(formerly RT/E/PS/00008)

- BS 6622, BS 6234, BS 7454

- IEC 60502-2, IEC60840

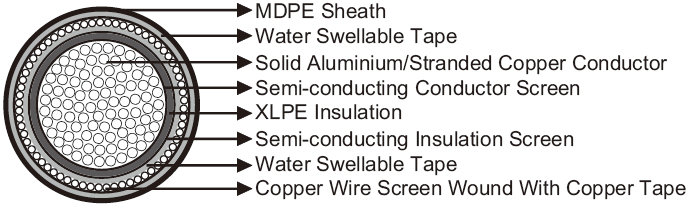

Cable Construction

|

|

- Conductors: Class 1 circular solid aluminium (for 185 mm^2) or class 2 compact circular stranded plain copper (for 300mm^2) to BS EN 60228: 2005 (previously BS 6360).

- Conductor Screen: Extruded semi-conducting XLPE (Cross-Linked Polyethylene) solidly bonded.

- Insulation: XLPE (Cross-Linked Polyethylene).

- Insulation Screen: Extruded semi-conducting XLPE (Cross-Linked Polyethylene), solidly bonded and cold strippable.

- Separator: Semi conducting water blocking tape.

- Screen: Copper wire screen, helically wound with equalising copper tape.

- Separator: Semi conducting water blocking tape.

- Sheath: Graphite coated MDPE type TS2.

Electrical Characteristics at 20℃

| Nominal Conductor Cross Section | mm^2 | 185 | 300 |

| Maximum DC Conductor Resistance | Ω/km | 0.164 | 0.0601 |

| Capacitance | μF/km | 0.205 | 0.243 |

| Voltage Rating | KV | 19/33 | 19/33 |

Mechanical and Thermal Properties

- Minimum Bending Radius: 15×OD

- Temperature Range: 0℃ to +90℃ (during operation); 0℃ to +60℃ (during installation)

Dimensions and Weight

| Cable Code | No. of cores& Nominal Conductor Cross Sectional Area No.×mm^2 |

Nominal Thickness of Conductor Screen mm |

Nominal Thickness of Insulation &Insulation Screen mm/mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|---|---|---|---|---|---|

| RF00008-RHZ1H16-19/33KV-1G185AL | 1×185 | 0.9 | 8.0/0.6 | 45.0 | 2200 |

| RF00008-RHZ1H16-19/33KV-1G300CU | 1×300 | 0.9 | 8.0/0.6 | 50.0 | 4500 |